Field Machining. Zero Downtime. Zero Disassembly. Zero Compromise.

World-Class Industrial Repairs In Your Backyard

Even the strongest assets wear over time. When every hour offline reduces production, and risks safety, compliance, and millions of dollars in preventable shutdown costs, many operators are forced to choose between integrity and profitability.

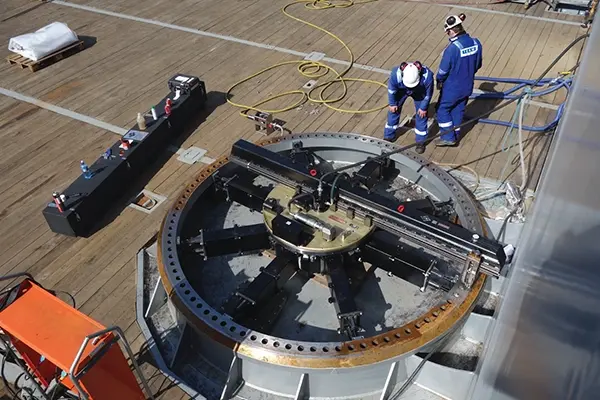

Field-machining delivers shop-grade precision in the field, restoring OEM tolerances faster, safer, and without disruption.

Why TEAM?

Broadest Tool Set:

Portable CNC rigs and self-leveling machines deliver OEM-grade accuracy anywhere.

Always Ready:

One of the largest tool fleets ensures fast mobilization and execution.

Seamless Integration:

Connects with Inspect360, Repair360, Detect360, and OneInsight for full lifecycle support.

Safety Built In:

Eliminates heavy lifts and teardown to reduce exposure and risk.

Featured Resources:

Brochure: Field Machining Services

Learn about factors that shape machining strategy, questions to ask before starting, and the full range of services.

Guide: The Ultimate Field Machining Playbook

Discover how portable, self-leveling machines deliver shop-quality precision in the field.

Case Study: Cutting Edge Casing Cutter for BP

TEAM designed and deployed an air-powered casing cutter to deliver precision cold cuts on high-grade steel in just 5 hours.

Your Next Step:

Stop choosing between asset integrity and profitability. Let’s restore your equipment faster, safer, and on your schedule together.